Volume Airflow Meter

Abbreviated VAM, a Volume Airflow Meter (also referred to as a Vane Airflow Meter), is an intake metering device that uses a mechanical vane which opens further as the intake manifold's vacuum increases.

Benefits

Generally speaking, a properly calibrated VAM can be more reliable and true to airflow than some MAF (Mass Air Flow) sensors. The mechanical aspects of the spring tensed vane offer fair sensor smoothing which can help greatly with an ECU reading the signal without the need for further circuitry present in factory MAF-equipped ECUs.

Limitations

The largest limitations with a VAM are: inlet size, mechanical hinderance, and weight.

Not only are VAM inlets square, which does not help with flow dynamics, but they tend to be rather limited in inlet area compared to the more easily manufactured round plastic MAF sensor housings. Though they often can support more than enough airflow for hundreds of Hp, the stock units equipped on vehicles such as the M20 and M40/42 are woefully small for higher output engines.

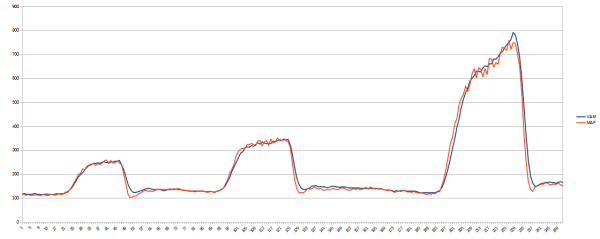

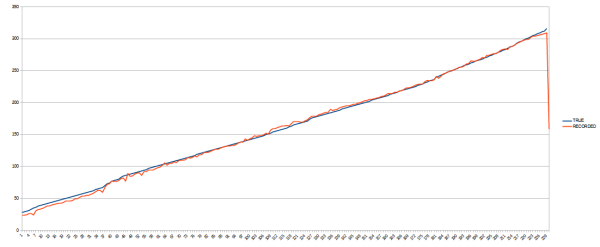

Mechanical hinderance in the form of the tensed vane can create very minor artificial tip-in lag. People refer to this as "throttle response". Many people claim better "throttle response" with a MAF as compared to a VAM. But is there any truth to this? The answer is... a bit. It's not as dramatic as many will claim. Below we can see a direct comparison of a VAM and a MAF installed in-line. The MAF uses the SSSQUID MAF Conversion Kit so there is some filtering done which is absolutely necessary for proper operation.

The major difference is in tip-out operation -- when the throttle is closed. The VAM's mechanical operation requires time for the vane to shut, while the MAF is able to detect the reduction in airflow much quicker. The opening of the vane is quite quick however since it is moved by vacuum, and the maf only has a slightly quicker operation.

Finally, the weight of a VAM is substantial compared to a MAF. A VAM will typically weigh 2-5 kg, whereas a MAF will weight just some odd-hundred grams. Running a MAF instead of a VAM will reduce weight and allow you to clear up more room in your engine bay.

Common Issues

Drop-out

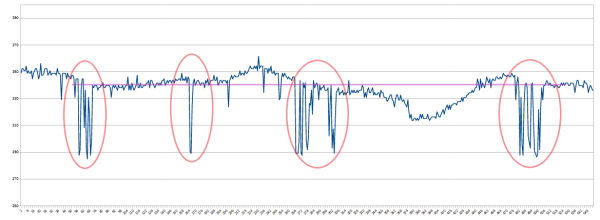

Drop-out is one of the most common issues with VAMs using a resistor pad (this is most every Bosch VAM). Drop-out is when the output signal drops well below where it should be or to null. This often occurs when the resistor pad has been worn through to the point where the contact arm is no longer able to make connection, or when damage has occurred to the resistor pad or contact arm.

Drop-out generally looks like the following image.

Adjustment

The next most common issue with VAMs is when the spring tension or arm offset have been adjusted by someone without a flow-bench. Making adjustments to these items is an unfortunately common procedure done by people ignorant of how these sensors and ECUs work.

ABSOLUTELY NEVER (NEVER EVER) MAKE AN ADJUSTMENT TO THE VAM WITHOUT A FLOW BENCH. NEVER (NEVER EVER) ADJUST THE VAM TO "MATCH" INJECTORS. THIS IS IMPROPER AND CAN LEAD TO ENGINE FAILURE. IF ANYONE SUGGESTS YOU DO THIS, RUN AWAY FAST.

There are two types of adjustments that can be made. To the contact arm, and to the spiral spring tension.

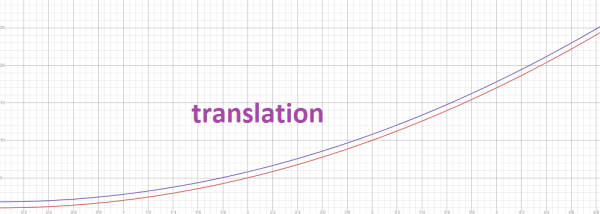

Adjustments made to the contact arm create a sensor output translation.

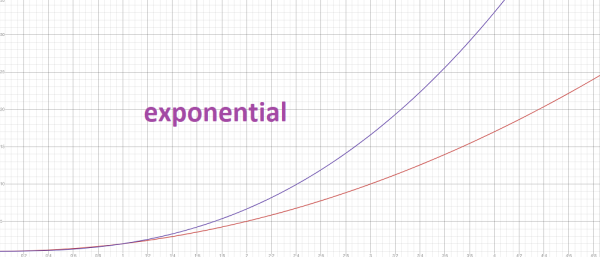

Adjustments made to the spring tension create a sensor output exponential adjustment.

Neither of these adjustments will correct for injectors properly. They will simply feed incorrect values to your ECU which will change everything from ignition timing to EGO sensor operation. Again, NEVER MAKE ANY ADJUSTMENTS WITHOUT A FLOW BENCH!!! We cannot stress this enough.

Repair

Repair generally involves replacing the resistor pad and placing the VAM on an airflow bench machine to match the sensor output to the manufacturer specified airflow calibration by making minor adjustments to spring tension and contact arm offset. Do not attempt this without a flow bench. Do not make adjustments to the spring tension or contact arm offset without a flow bench. This cannot be stressed enough. Improper adjustments can lead to complete engine failure.

A properly calibrated VAM will output a signal that matches the sensor maths in your ECU's software. An example of a properly calibrated VAM follows: