VAM to MAF Conversion

SSSQUID MAF Conversion Kit

View instructions and read more about our conversion kit here: SSSICK

The SSSQUID Input Conversion Kit (SSSICK) is available in pre-release format. It was previously known as the SSSQUID MAF Conversion Kit (SSSMCK), but we have expanded its capabilities to handle multiple different inputs, include manifold air pressure sensors (MAP) and throttle position sensors (TPS). You can read more and purchase it here: SSSICK

Introduction

While both a VAM (Volume/Vane Airflow Meter) and a MAF (Mass AirFlow meter) do the same basic job, it's widely considered that a MAF sensor has quicker airflow metering. In general they also increase overall intake efficiency by reducing and removing physical restrictions.

A VAM consists of a mechanical vane that is held closed by a spiral tension spring. As the air pump (engine) attempts to draw air into the cylinders, vacuum acts against the vane and opens it to allow airflow in. The larger the vacuum generated by the engine, the wider the vane opens. This opening is translated to a potentiometer (usually in the form of a resistor strip) that converts a reference signal (usually 5 volts) into an output signal to the ECU. When closed, the VAM outputs near 0 volts. When fully open, it will output a signal closer to 5 volts (the input reference voltage). The VAM can only sense airflow in one direction. Due to the mechanical nature of a VAM, it acts as its own filter and provides a rather steady signal.

A MAF often consists of a heated element or film, which is also referred to as an HFM, or Hot/Heated Film Meter. Unlike a VAM, it does not have any moving components and can sense airflow in both directions as an absolute, however it's airflow routing is only designed to be read in one direction. It's not foolproof, and it can still sense airflow to a degree in the opposite direction. This results in a signal that has many peaks and valleys, and is not pre-filtered.

Converting from a VAM to a MAF requires more than just changing the VAM to a MAF. It requires specialized conversion equipment to correctly read the MAF, filter it, and output a signal that the stock ECU is capable of reading correctly.

Furthermore, a MAF's output curve is not exponentially plottable, whereas a VAM's output curve is. This necessitates using individual cells to plot a MAF's curve, whereas a compound exponential equation is used to produce a VAM's curve. This must be done programmatically. It is nearly impossible to tune a VAM-equipped ECU to be used with a MAF without the use of conversion circuitry. They are not in any way compatible in terms of electronics, output signals, and reference signals. A conversion kit MUST be used when converting from a VAM to MAF.

Benefits

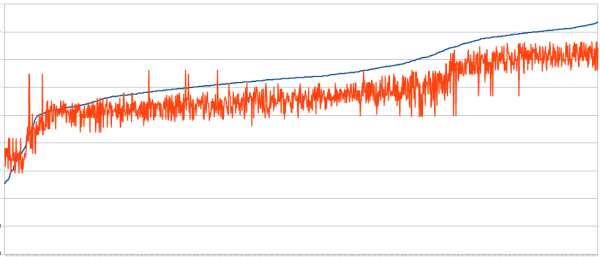

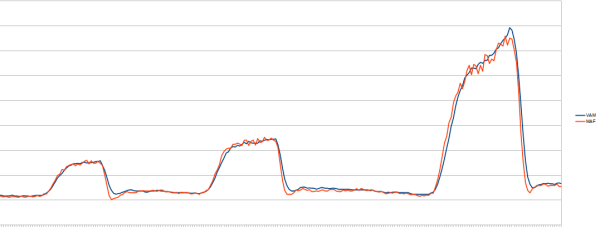

The most obvious benefit of a MAF over a VAM is what people colloquially refer to as "throttle response", or how quickly an engine responds to throttle position changes. This can be visualized with a raw Kg/Hr comparison of a MAF processed through our SSSMCK and a VAM below:

Hardware

The SSSICK offers the necessary hardware and software to convert a MAF, MAP, or TPS signal to something that the stock ECU is capable of correctly reading. Our kit can even be used with the stock tune! No specialized tuning is required. The SSSQUID ICK is currently the ONLY retail kit that is able to do this.

Availability

This kit is now currently available at the retail level. You can view its listing here: SSSICK base kit

We produce all of our products in-house and through local small businesses, which makes production costs exponentially higher than outsourcing to modern day slave-labor overseas like other companies. Yes, even the circuit boards themselves are produced (not just assembled) right here in The United States using as much recycled material as possible, and in a facility that is solar-energy powered!