Spark Plugs

Sorry for the sparse information, we are writing this as time allows.

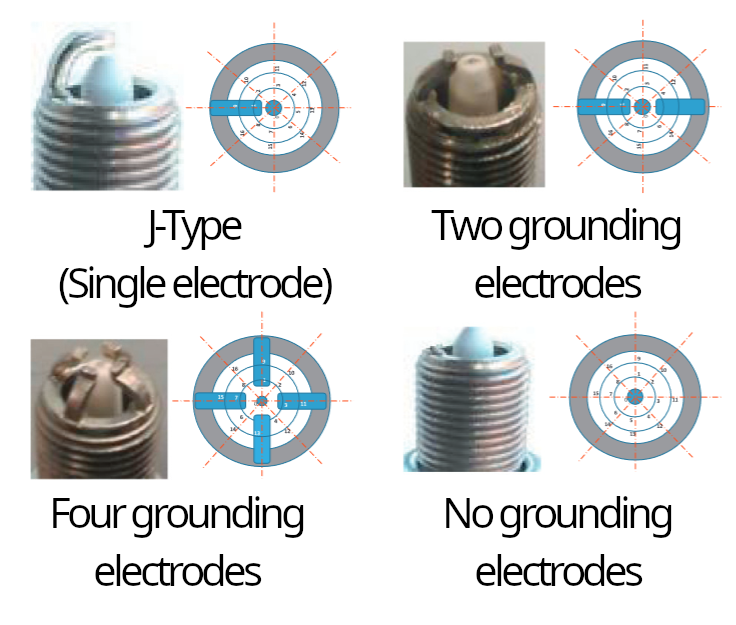

Electrode

There are a number of grounding electrode designs are available. The most common is a single strap plugs have a single grounding electrode . TT plugs have a piece of electrode extruded from both the anode and the cathode. They generally produce a superior spark at a lower gap, thereby increasing overall efficiency of the ignition event. Their major downfalls would be increased cost (generally about 20-50% more expensive) and decreased longevity. As spark plugs fire, their electrodes erode. Having both the anode and cathode with a needle (or tip) means that they must be coated in expensive metals, such as platinum, and therefore reach a period of decreased operation with fewer ignition events.

Design

There are 5 basic electrode designs. 4 of these are illustrated below:

A fifth, less popular design utilizing three grounding electrodes is also available from Denso.

The number and design of grounding electrodes has a direct effect on combustion cycle, which changes the time at which a cylinder reaches peak pressure. This means changes in tuning are necessary depending on the type of plug used.

Admed A Abdel-Rehim published a fantastic paper comparing these types of electrodes which this article will draw heavily upon. [1]

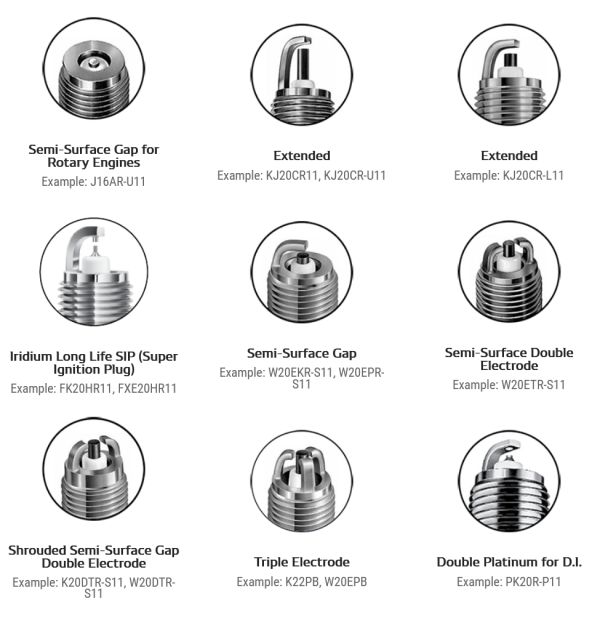

Within those 4 basic designs, you will find dozens of fine-detail variations. Below you can see the various types of electrode designs that Denso manufactures:

Generally speaking, plugs with no grounding electrodes provide the most consistent pressure delta cycle-over-cycle (PDCC). This is because there is no obstruction between the spark kernel and the combustion chamber, whereas each other design with an overhanging or extended grounding electrode has at least one side of obstruction that alters how the spark kernel spreads into the combustion chamber. The zero electrode design also provides the highest cylinder pressure maximum measured.

The indicated mean effective pressure (IMEP) is a way of measuring how effective the combustion phase it against the piston. A higher IMEP rating means a more efficient combustion phase. IMEP is measured by kPa average of acting force against a piston for 180 ignition cycles. The IMEP ratings of the 4 basic types of electrode design are as follows:

- No electrode: 147.30

- Four electrodes: 145.20

- Two electrodes: 144.00

- Single electrode: 141.06

What we can deduce by this is that a no electrode plug is the most efficient design, with the single electrode design being the least -- a difference of 4.4%.

So, why aren't all plugs designed with multiple electrodes, or zero?

More electrodes increases instability in flame propagation. Spark always searches for the path of least resistance, and as heat increases there is an increasing chance that a spark kernel will not be achieved between all of the multiple electrodes. This is especially true for zero electrode plugs, where spark happens anywhere in a 360' range. Increasing the number of paths a spark may take increases engine instability.

A zero electrode design also increases the distance in which a spark must jump, which often means increased current required. Higher performance or over-driven coils may become necessary at this point.

All of these factors combine to mean that the air-fuel mixture in your cylinder will combust at a different rate, and some setups may require drastically different tuning than another.

If you are in doubt as to which to use, please feel free to contact us directly!

Material

You'll notice there are many different materials used in the electrodes of spark plugs. The most common are: copper, platinum, iridium, and gold.

Gap

Almost every single plug you purchase will have their gap set from the factory. It's rather rare that you will need to change this at all.

Gap size depends on a few things, most notably electrode design and cylinder compression.

Initial gap sizes are determined by the plug manufacturer. Most standard design electrodes will have a gap between 0.6-1.1 mm (0.022-0.043 in), and this depends on a great number of factors. Consult the manufacturer's specifications and start with that gap.

As you increase the gap, you exponentially increase the amount of current required for the plug to generate spark. When the gap is increased, an ignition system upgrade is required to provide enough current for the plug to produce spark. So why increase the gap at all? To a certain extent, increasing the gap increases overall fuel ignition efficiency. A larger spark increases how much mixture ignites in a certain time period. However, at a certain point, this can cause spark blow out or the ignition event occurring too quickly and actually losing efficiency or causing too high pressure. Therefore it's important to start at the manufacturer recommended gap and not deviate too far from that.

All being said, perfecting the gap for maximum power is only worth about 0.1-1.0% increase in power over an "inappropriate" (but working) gap. So setting gap for longevity and consistency of operation is the best idea unless you are an F1 engineer.

As you increase cylinder compression, either through mechanical compression (pistons/comchams/stroke) or through forced induction (turbocharger/supercharger), spark blowout becomes an increasing possibility. Therefore it becomes necessary to decrease the electrode gap.

The two most popular plug manufacturers will be discussed below. Of the two, Denso is the far superior and recommended brand.

ALL Denso Iridium TT plugs have an initial gap of 1.0 mm (0.039 in). It should almost never be increased, though it can be decreased to as little as 0.6 mm. Other Denso plug gaps are: Iridium Power (0.7-1.1 mm), Iridium Racing (0.6-1.0 mm), Iridium Tough (0.8-1.1 mm), Iridium Plus (all are 0.8 mm).

NGK plugs generally have a gap of between 0.4 - 1.0 mm. NGK recommends increasing the gap by about 0.05-0.08 mm (0.002-0.005 in) for every 200 hp over 200 hp. However, it's also recommended to REDUCE that gap by about the same amount for every compression ratio increase of 2:1 or about 0.5 bar (7.7 psi) of added forced induction. As you can see, it is a delicate balance.

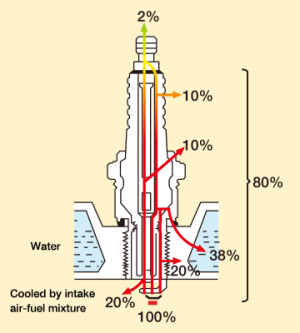

Heat Rating

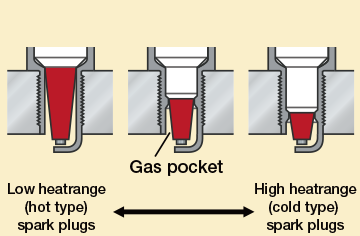

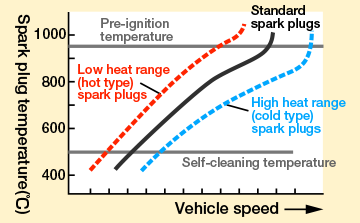

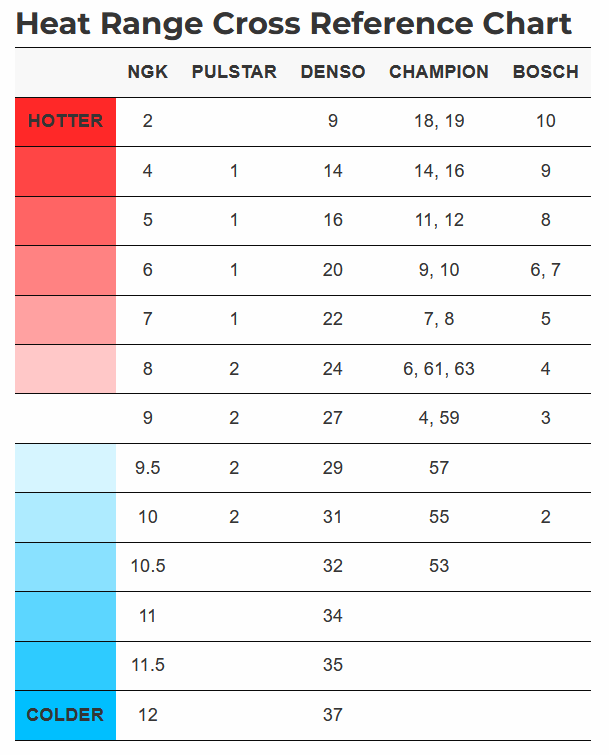

Otherwise known as temperature, your spark plug's heat rating needs to be selected depending on your engine's operating temperature. If you continually drive shorter distances on the street, it's most likely best to choose the default heat rating for your engine. If you have a highly modified engine that is regularly raced or driven hard, you may need to choose a higher heat range plug (or a "colder" plug).

The heat range refers to how much heat the plug dissipates. A "colder" plug will dissipate more heat through it's ceramic insulation. A "hotter" plug will dissipate less and retain more heat. A certain level of heat is necessary for proper spark operation, but too cold or too hot for your engine and situation will have negative effects.

The insulation length and size is a primate determining factor in a spark plugs heat range. A "hotter" plug (a colder-range plug) will have the most insulation to reach and remain at the proper operating temperature easier, while a "colder" (a hotter-range) plug will have the least insulation so that it dissipates heat more easily.

Spark plugs must reach self-cleaning temperature in order to remain operating properly. This is about 500'C. Below 500'C, carbon from unburnt fuel attaches to the electrodes and degrades their performance. This is why vehicles that are driven at low loads for short distances need hotter plugs.

However, hotter plugs higher retention of heat can lead to pre-ignition when used in high performance engines that are driven at high loads for longer periods of times. If this is your circumstance, it may become necessary to use a colder plug (a plug of a higher heat-range)

Heat range chart

Maintenance

How often should you replace your plugs? That depends entirely on design and use! Most plugs for street-driven vehicles are recommended to be replaced somewhere between 15,000-30,000 kilometers or 10,000-20,000 miles. This works out to about once every 12-18 months for many folks.

Of course, this is the recommended for prime operation. Most of these plugs can easily be stretched to 50,000 km or more without most people noticing. As plugs wear, the voltage required to drive the spark increases. Since most factory-tuned vehicles are tuned specifically for worn parts and poor quality fuel, this means you should not run into running trouble when driving plugs longer than intended.

If you want to avoid any possible trouble, there are also long-life plugs that are designed to be used up to 100,000 km / 62,000 mi before you need to consider replacing them.

If you are racing your engine, you will certainly need to replace your plugs more often.

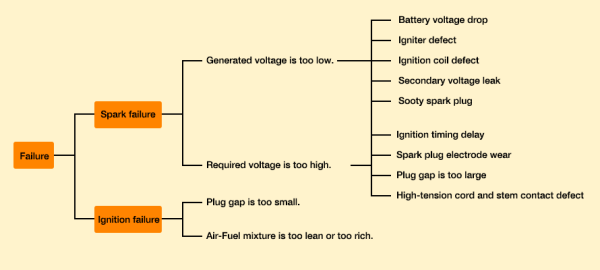

When do I absolutely NEED to replace a plug? When you run into misfires.

Diagnostic

Fouling

Carbon fouling

| Appearance | The insulator foot section and electrode section are covered with dried, soft black carbon. |

|---|---|

| Results | Poor starting, misfiring, acceleration defect. |

| Cause | Repeated short-distance driving (driving with the engine cool), incorrect choking (overly rich air-fuel mixture), injection timing delay, plug heat range too high. |

Oil fouling

| Appearance | The insulator section and electrode section is black and lustrous with wet oily deposits. |

|---|---|

| Results | Poor starting and misfiring. |

| Cause | Oil leaking due to piston ring, cylinder, or valve guide wear (occurs easily to new engines and engines that have just been overhauled), high oil content in air-fuel mixture.(2-stroke engines) |

Fuel fouling

| Appearance | The spark plug is wet with gasoline immediately after it is removed, but it soon dries off. |

|---|---|

| Results | Poor starting and misfiring. |

| Cause | The air-fuel ratio is too rich and is not igniting. (Among the ways this can happen is if the driver presses the accelerator over and over while starting the vehicle.) |

| Handling | Remove all the spark plugs, crank the starter motor to bring fresh air into the cylinder and make the air-fuel ratio leaner. |