M20 and Forced Induction: Difference between pages

(→Intake) |

|||

| Line 1: | Line 1: | ||

=Introduction= | |||

= | =Fueling= | ||

If you are looking for a tool to estimate injector flow required, please check [https://sssquid.com/v3/choosing-fuel-injectors/ HERE]. | |||

= | =Power= | ||

In general, you can expect a gain of 3-5 lb/ft of torque per pound of positive pressure added for every 1.0 litre of engine displacement . E.G. on a 2.5 litre engine, 10 PSI will add between 75 and 125 ft/lb of torque. | |||

=Intake Airflow Sensors= | |||

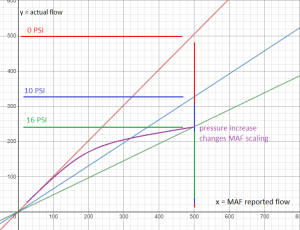

Any intake metering device ''should'' be within the intake track of the turbo (know as "draw thru" or "pull thru"). It is not recommended to place your intake metering device (VAM, MAF, HFM, etc) in the charge-pipe (known as "blow thru") unless it is a specifically designed piece of hardware that can properly read a pressurized system. This is because these systems are designed to meter airflow at atmospheric levels (corrected for air temperature in the ECU). Therefore, when pressures are different than atmospheric, reported airflow becomes drastically different than actual airflow. A graph (fig. 1) illustrates this effect in terms of positive pressure. | |||

[[File:MAF_compare_forced_induction_blow-thru_3.png|thumb|fig. 1 - A comparison of reported airflow by a MAF under different positive pressures.]] | |||

While it is possible to use a MAF as a blow-thru style, it will give you incorrect readings. | |||

' | * Why is this important? | ||

** Because every aspect of your engine's operation is determined by intake flow rate, most notably: ignition timing, fueling, knock correction, and idle control. | |||

* Why does it matter if it reads differently at +8 PSI than at +0 PSI? Can't you just tune for that? | |||

** +8 PSI can have the same actual airflow as +0 PSI depending on a number of factors such as throttle position and RPM. | |||

** As a generic example, 250 kg/hr airflow at atmos (+0 PSI) reports 250 kg/hr to the ECU. However, 250 kg/hr at +8 PSI reports about 500 kg/hr to the ECU. | |||

*** This means any tune would be created for one circumstance and not the other. | |||

It is worth noting that no retail "blow-thru" MAF we've tested have worked as advertised, and all have been standard MAFs, sometimes with a resistor added. | |||

== | =Manifold Air Pressure Sensors= | ||

Almost every factory-equipped F/I vehicle is equipped with a MAP (Manifold Air Pressure) sensor. This sensor, in conjunction with an intake-tract airflow sensor, provide an exact intake rate and cylinder pressure to an ECU. Manifold pressure is indicative of cylinder pressure (engine efficiency), which drastically affects tuning choices. | |||

When converting from N/A to F/I, it is highly recommended to use an ECU that can read manifold pressures (such as MegaSquirt). However, it is possible to add a MAP sensor to most any Motronic ECU through a piggyback converter board (available [https://sssquid.com/ here]). | |||

== | =Alpha-N= | ||

[[Alpha-N]] is a tuning solution utilizing the TPS (throttle position sensor) and vehicle RPM. This is not a good tuning solution for turbocharged vehicles, and is also a poor solution, but to a lesser degree, for supercharged vehicles. | |||

Revision as of 18:24, 5 February 2021

Introduction

Fueling

If you are looking for a tool to estimate injector flow required, please check HERE.

Power

In general, you can expect a gain of 3-5 lb/ft of torque per pound of positive pressure added for every 1.0 litre of engine displacement . E.G. on a 2.5 litre engine, 10 PSI will add between 75 and 125 ft/lb of torque.

Intake Airflow Sensors

Any intake metering device should be within the intake track of the turbo (know as "draw thru" or "pull thru"). It is not recommended to place your intake metering device (VAM, MAF, HFM, etc) in the charge-pipe (known as "blow thru") unless it is a specifically designed piece of hardware that can properly read a pressurized system. This is because these systems are designed to meter airflow at atmospheric levels (corrected for air temperature in the ECU). Therefore, when pressures are different than atmospheric, reported airflow becomes drastically different than actual airflow. A graph (fig. 1) illustrates this effect in terms of positive pressure.

While it is possible to use a MAF as a blow-thru style, it will give you incorrect readings.

- Why is this important?

- Because every aspect of your engine's operation is determined by intake flow rate, most notably: ignition timing, fueling, knock correction, and idle control.

- Why does it matter if it reads differently at +8 PSI than at +0 PSI? Can't you just tune for that?

- +8 PSI can have the same actual airflow as +0 PSI depending on a number of factors such as throttle position and RPM.

- As a generic example, 250 kg/hr airflow at atmos (+0 PSI) reports 250 kg/hr to the ECU. However, 250 kg/hr at +8 PSI reports about 500 kg/hr to the ECU.

- This means any tune would be created for one circumstance and not the other.

It is worth noting that no retail "blow-thru" MAF we've tested have worked as advertised, and all have been standard MAFs, sometimes with a resistor added.

Manifold Air Pressure Sensors

Almost every factory-equipped F/I vehicle is equipped with a MAP (Manifold Air Pressure) sensor. This sensor, in conjunction with an intake-tract airflow sensor, provide an exact intake rate and cylinder pressure to an ECU. Manifold pressure is indicative of cylinder pressure (engine efficiency), which drastically affects tuning choices.

When converting from N/A to F/I, it is highly recommended to use an ECU that can read manifold pressures (such as MegaSquirt). However, it is possible to add a MAP sensor to most any Motronic ECU through a piggyback converter board (available here).

Alpha-N

Alpha-N is a tuning solution utilizing the TPS (throttle position sensor) and vehicle RPM. This is not a good tuning solution for turbocharged vehicles, and is also a poor solution, but to a lesser degree, for supercharged vehicles.