Fuel Pump

Use our FUEL PUMP CALCULATOR!

Introduction

A very common question is what size fuel pump is needed for a certain engine output. This page will discuss how to size your fuel pump.

Something we must touch on first, however, is that fuel pumps DO NOT ADD MORE POWER. The amount of people that ask "how much power will this fuel pump give me" is immense. Just like choosing injectors, you size your fuel pump to match your engine's output. Adding a larger fuel pump will not increase your engine's power output by itself.

Generally you will want to size your fuel pump to handle about 20-30% more power than your engine outputs. It's generally not a good idea to use a fuel pump that provides a significant amount more fuel than your vehicle uses, even if there is a fuel return system.

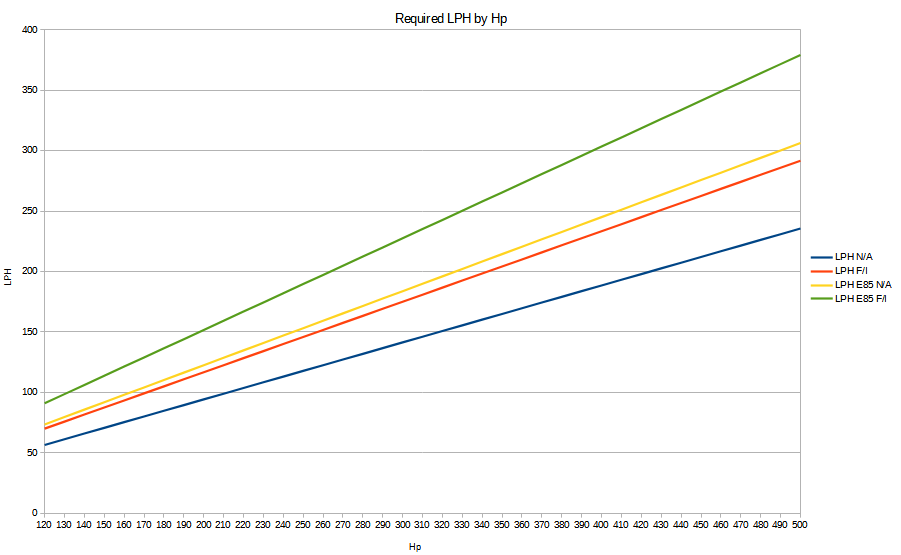

Generally, for most N/A vehicles, you can simply take your Hp output and multiply by 0.5 (or divide by 2) to get your required LPH. E.G. a 300 Hp vehicle will require a 150 LPH fuel pump.

Generally, for most F/I vehicles, you can simply take your Hp output and multiply by 0.62 to get your required LPH. E.G. a 300 Hp vehicle will require a 190 LPH fuel pump.

If you'd like to learn more, please continue reading!

Return vs non-return

What is a fuel return system? There are two types of fuel systems: return system and non-return system.

A return system has an in-tank fuel pump that works at a set rate (or range of set rates depending on engine load). It pumps fuel into a fuel rail that has a fuel return line with a fuel pressure regulator installed on it. The fuel pressure regulator will mechanically control the fuel pressure. These can become overloaded if the fuel pump is oversized and pressure will increase beyond it's designed throughput limit. Therefore it's important to size your pump in accordance with your vehicle's output. If your vehicle is capable of having multiple set pump rates, it's important to have your vehicle's ECU tuned to match the pump rate as to not overload the regulator.

A non-return (or "returnless") system will have a pump and regulator in-tank along with a series of sensors throughout the system. A computer will control the pump in order to produce a specific pressure within the system. This system typically uses less power than a returning system, but is a bit more complicated and it can run into serious issues without extensive fuel pump computer tuning (usually controlled though the ECU, but sometimes can be a separate controller) when running larger pumps. This is a more modern solution and can be superior to a return system when sized and tuned correctly.

Calculating LPH

Calculating how much fuel (in LPH) is used by your vehicle is rather simple:

L = (A / R) * (3600 / 737)

Where:

- L = Litre per hour of fuel

- R = air-fuel ratio (12.5 to 13.5 for N/A vehicles, 10.5 to 12.5 for F/I vehicles)

- A = airflow in g/sec -- you can estimate airflow g/sec by: A = Hp * (0.7 + F), where:

- F = engine efficiency (an average of 0.5 can be used for most vehicle)

- 3600 / 737 * A : We convert airflow in grams/second to litres/hour. There are 3600 seconds in an hour. There are 737 grams of fuel in 1 litre at 23'C.

Easy! Generally you will want to size your fuel pump to handle about 20-30% more power than your engine outputs. But... there's one more step! Read the next section on how fuel pressure affects flow rate....

Fuel Pressure and LPH

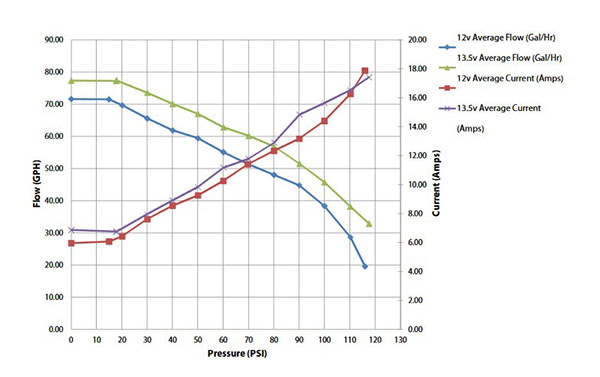

A fuel pump's advertised rate is its "free-flow" rate, or how much fuel it can pump with no additional system pressure. However, fuel systems are pressurized. With fuel-injected vehicles, this tends to be between 36.75 to 73.5 PSI. As pressure increases, flow rate decreases.

Summit racing has a great chart to show how this works (read more here):

Final

The final equation, with pressure and safety margin taken into consideration:

L = (A / R) * (3600 / 737) * 1.2 * S

Where all variables are the same as described before, but now includes the pressure scalar (for many fuel pumps there is about a 0.5% decrease in flow for every 10 PSI over 20 PSI (up to 100 PSI):

- S = F / C

- F = free-flow LPH

- C = F - (F * 0.005) * ((P - 20) / 10), where:

- C = calculated flow LPH

- P = system pressure

- 0.005 is another way to write 0.5/100 (or 0.5%)

- This is only useful between 20 and 100 PSI system pressure

Let's view an example of a standard engine with an efficiency of 0.5, a fuel system pressure of 50 PSI, and with a few configurations (N/A 13 AFR, F/I 10.5 AFR, and N/A E85)

Rounding these values, we can see a few examples below:

Hp - safe LPH rating N/A - F/I

- 150 Hp - 70 LPH - 90 LPH

- 200 Hp - 95 LPH - 120 LPH

- 250 Hp - 120 LPH - 145 LPH

- 350 Hp - 165 LPH - 205 LPH

- 500 Hp - 235 LPH - 290 LPH

Size Appropriately

A fuel pump will not add any engine power by itself. Instead, you should size your fuel pump to your engine's output.

Running a fuel pump that is too large for your engine output will:

- Increase required power to run the pump -- therefore decreasing power to the wheels.

- Increase fuel system temperature

- This decreases the density of fuel. Fuel density is directly related to its temperature. A higher temperature fuel will be less dense, which requires longer injection times and more effort to meet your AFR goals.

- May increase fuel system pressure

- If you size too large, the fuel pump can overwhelm a return system pressure regulator. It may also affect a non-return system by operating outside the range which the fuel pump controller can operate without modification/tuning.

- This will throw off tuning significantly as more fuel is being released through the injectors during each injection phase.

- May wear fuel system components faster.

- More effort to pump fuel, higher pressure, and more fuel running through each component means quicker wear, especially on filters, pumps, and pressure regulators.

For those reasons, among a few other less important aspects, it's important to size your fuel pump to match your engine. Please, please, please stop installing 300 LPH fuel pumps on your 150 Hp vehicle. Please.