Filter Testing

Introduction

There is a large amount of misinformation floating around in regards to filter performance and intake needs. Tired of this, we've decided to do some proper filter testing. These results will be added to as we test more and more systems, but this is a very low priority in comparison to the other work that needs to be done. If you have a specific filter you want tested, please CONTACT US!

Testing Procedure

Each set of filters will be tested and grouped according to their connection diameter. The diameter of the connection has a direct affect on the airflow they allow.

All tests are repeated at least 3 times. If any test is significantly out of range, it is discarded and tested again until all tests are within less than 2% of each other. The middle-reading test is chosen for use and display in the graphs shown.

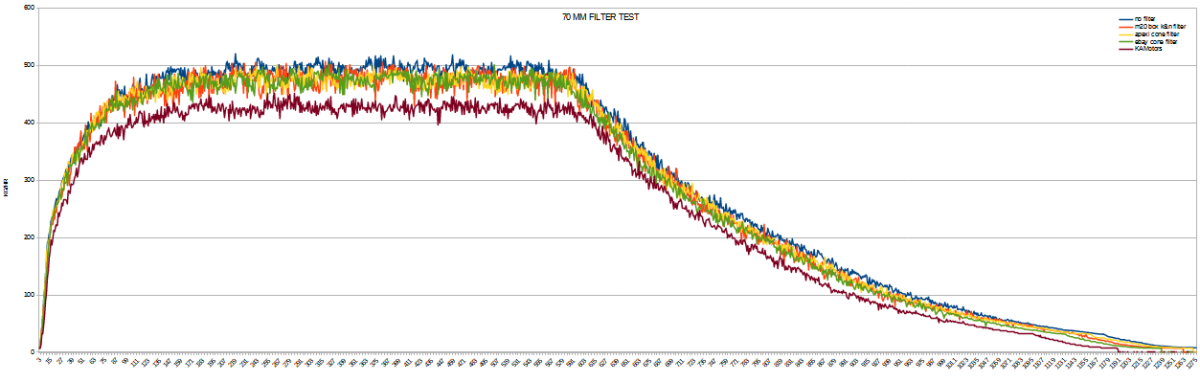

Each filter is installed on our flow machine, which has a maximum of a 100 mm (4 inch) inlet. It is capable of moving air at a rate of up to 750 CFM. The machine spools quickly, is held at full load for a set amount of time, and then is turned off. This gives us three areas of observation: spool-up, maximum flow, and spool-down.

Spool-up will give us an idea of how quickly the machine is able to reach max flow. This is an indication of how quickly an increasing airflow is able to move through the filter and system. This could be equated to "throttle response".

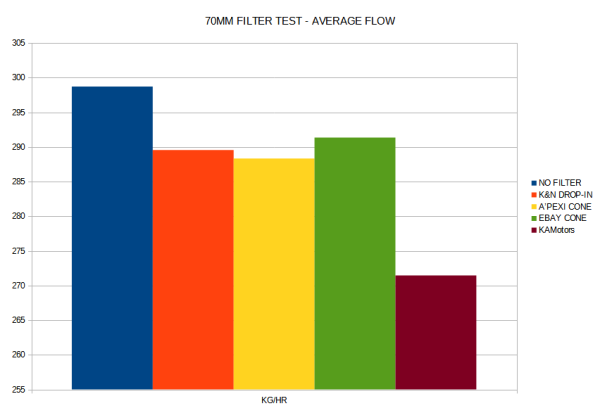

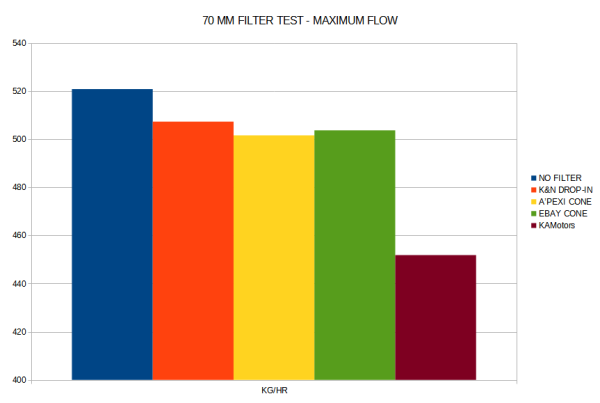

Maximum flow gives us an idea of how much airflow a filter is capable of allowing with an identical system. A higher max flow could be equated to a higher potential engine output, or "power".

Spool-down is when the turbine of the machine is freely rotating while decreasing in speed from peak RPM. The more difficult it is for the system to draw in air, due to a lower filter efficiency coefficient, the quicker the system returns to a halt. The longer the "tail" is -- the downward trend after max flow -- the higher the filter throughput efficiency is. This could be equated to a higher overall intake efficiency potential.

As the restriction coefficient of a filter increases, we will see a slower increase from 0 to peak, a lower max flow rate, and a quicker return to 0 from peak. A better filter or intake system will have a quick spool-up time, a high max flow rate, and a slow spool-down time.

Results

Results will be constantly added to as we have time to test more filters.

70 mm

So far, the filters tested are:

- K&N drop-in filter used in an M20B25 intake box

- a no-name generic cone filter from eBay (130 mm height by 150 mm width, with a center inset conical filter as well as filter on the outer side of the cone)

- Apexi "TYPE-3 POWER FILTER" cone filter.

- KAMotors ($30 ebay intake with a $100 sticker put on it) enclosed cone-type filter

The obvious advantage here goes to running without any filter ("no filter"). There is little to choose from between the next three options: the K&N drop-in filter, the Apexi cone filter, and a no-name generic ebay cone filter. There is an obvious outlier here, which is the KAMotors intake, which is a cone filter enclosed in a carbon fibre tube. Its flow rate is significantly lower than that of the other filters.